Under increasingly stringent environmental requirements today, low NOx burners and low-NOx combustion technologies have become key development directions in the industrial combustion sector. As a professional low-nitrogen burner manufacturer, we are committed to providing efficient, energy-saving, and environmentally friendly low-nitrogen burners and combustion system solutions, helping enterprises achieve ultra-low emissions of nitrogen oxides (NOx) and meet national environmental standards.

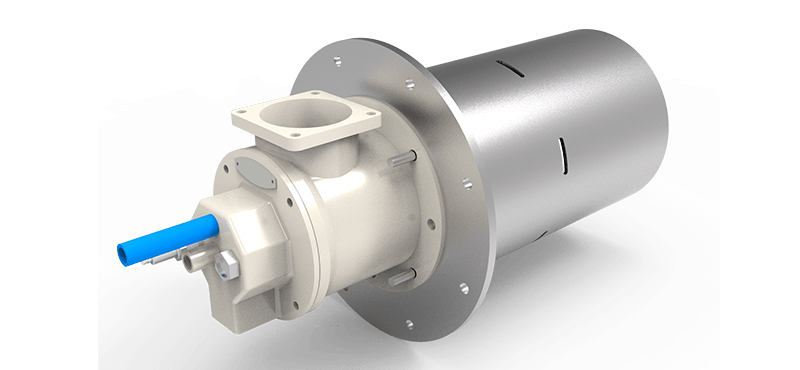

(Low NOx Burner)

The core of low-nitrogen combustion technology lies in optimizing the combustion process to reduce flame temperature and minimize the generation of nitrogen oxides. Traditional combustion methods often result in high NOx emissions due to elevated temperatures, whereas modern low-nitrogen burners employ advanced technologies such as staged combustion, flue gas recirculation (FGR), and premixed combustion to effectively suppress NOx formation. For example, low-nitrogen burners achieve more thorough combustion and lower peak temperatures by precisely controlling the air-fuel mixture ratio, thereby reducing harmful gas emissions.

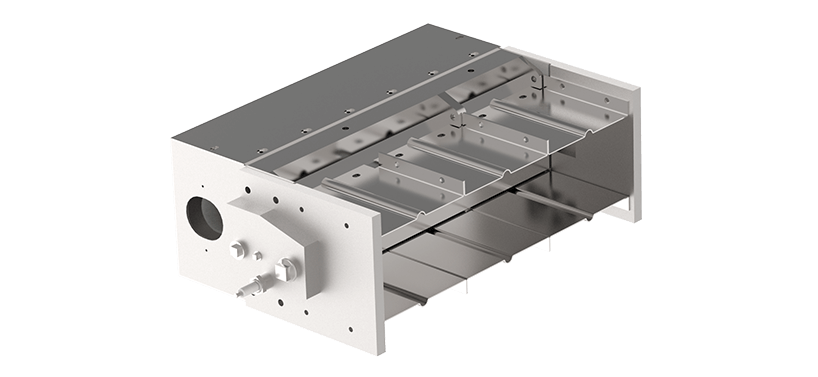

(Low NOx Duct Burner)

The low-nitrogen burners developed and produced by DYDTEC generally achieve NOx emissions below 50mg, and under specific conditions, can even reach ultra-low NOx emissions of 20mg.

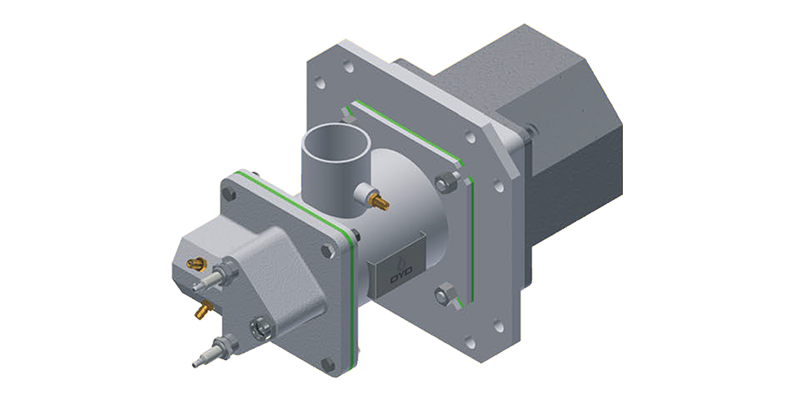

Low-nitrogen burners are widely used in industrial settings such as boilers, heat treatment furnaces, smelting furnaces, and drying equipment. Whether for gas, oil, or dual-fuel systems, efficient and clean combustion can be achieved through customized low-nitrogen combustion technology. In industries such as petrochemicals, metallurgy, ceramics, food processing, paint drying, and light textiles, our low-nitrogen burners have earned the trust of numerous customers due to their stability and low-emission characteristics.

(High Speed Low NOx Burner)

As an experienced low-nitrogen burner manufacturer, we not only provide high-performance combustion equipment but also offer comprehensive technical support, including combustion system design, installation, commissioning, and post-maintenance. Our low-nitrogen combustion technology has passed multiple environmental certifications, ensuring reduced NOx emissions while improving combustion efficiency and minimizing energy waste.

(Low Nitrogen Burner Factory of DYDTEC)

With the continuous advancement of environmental policies, adopting low-nitrogen burners and low-nitrogen combustion technologies has become an inevitable choice for industrial enterprises. DYDTEC owns a 11,000㎡ R&D and production base and employs 150+ engineers. As a leading low-nitrogen burner manufacturer, we will continue to innovate, providing customers with more efficient and environmentally friendly combustion solutions to promote green manufacturing and create a sustainable future. For more product information or technical consultation, feel free to contact DYDTEC anytime!