A duct burner is a critical component in gas turbine systems, designed to enhance thermal efficiency and power output. Installed in the exhaust duct of a gas turbine, duct burners utilize residual oxygen in the exhaust gases to produce additional heat, making them ideal for combined-cycle power plants, cogeneration systems, and industrial heating applications.

This article explores the functionality, benefits, applications, and key considerations of duct burners, providing valuable insights for engineers, plant operators, and industry professionals.

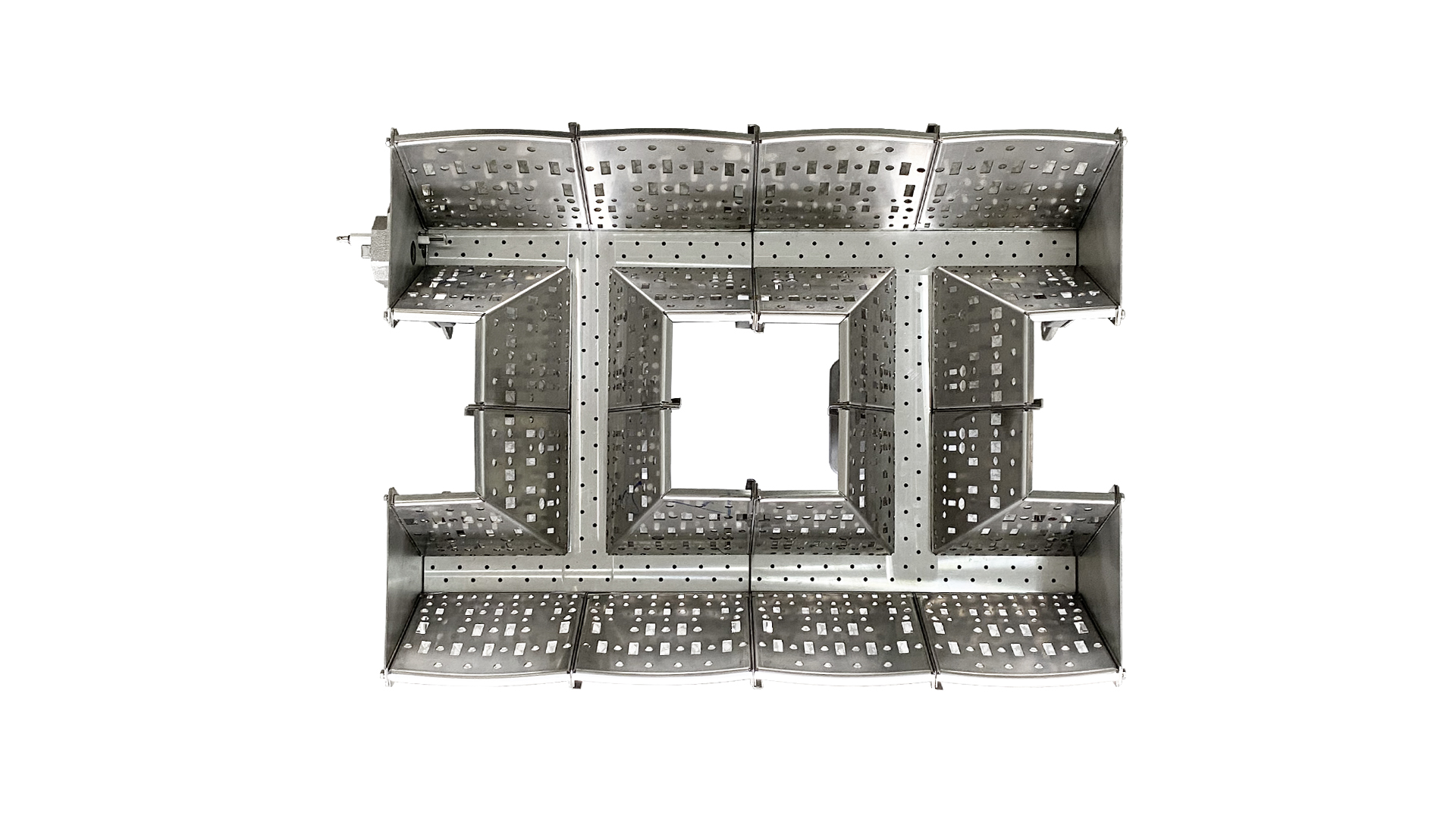

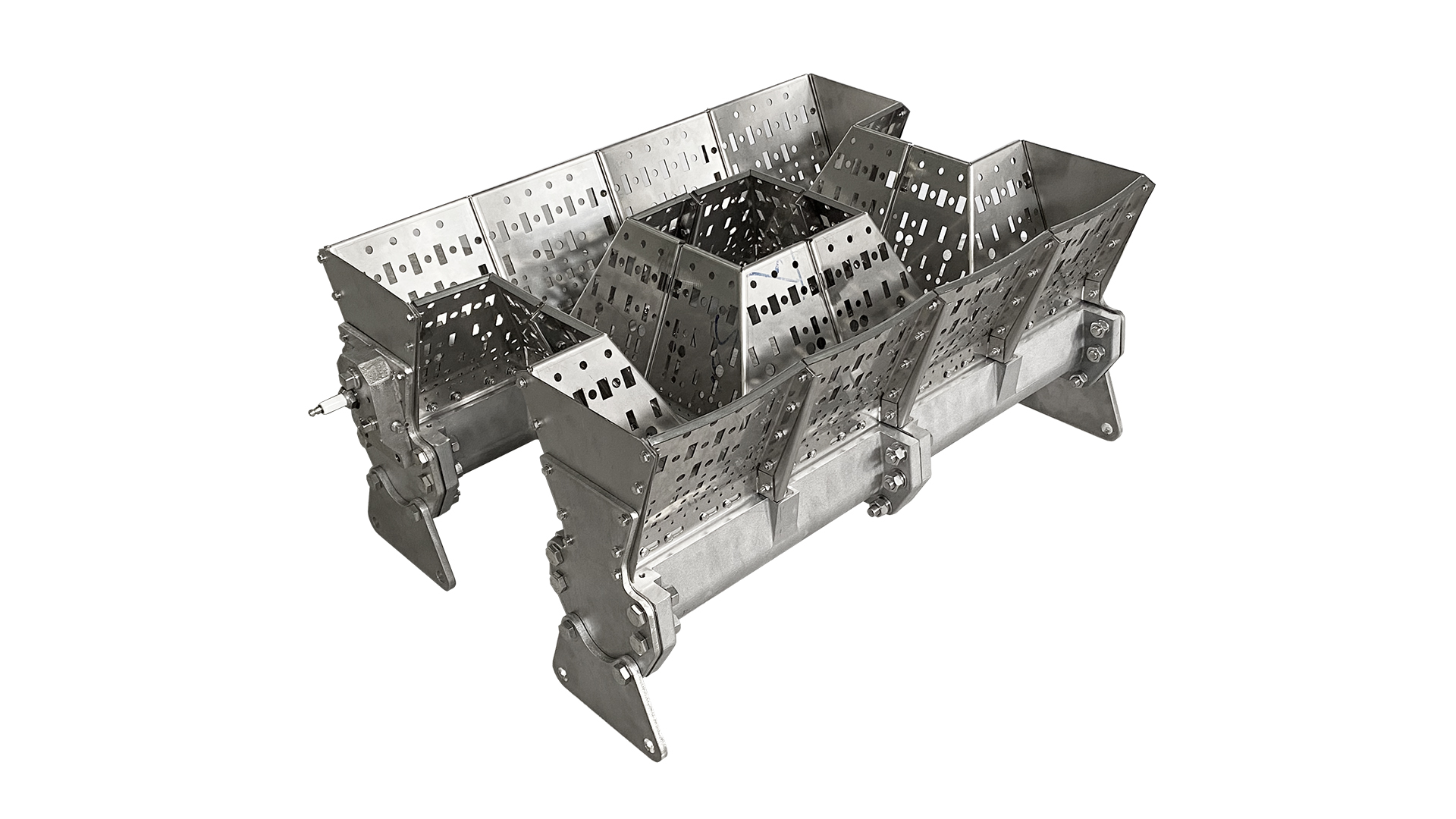

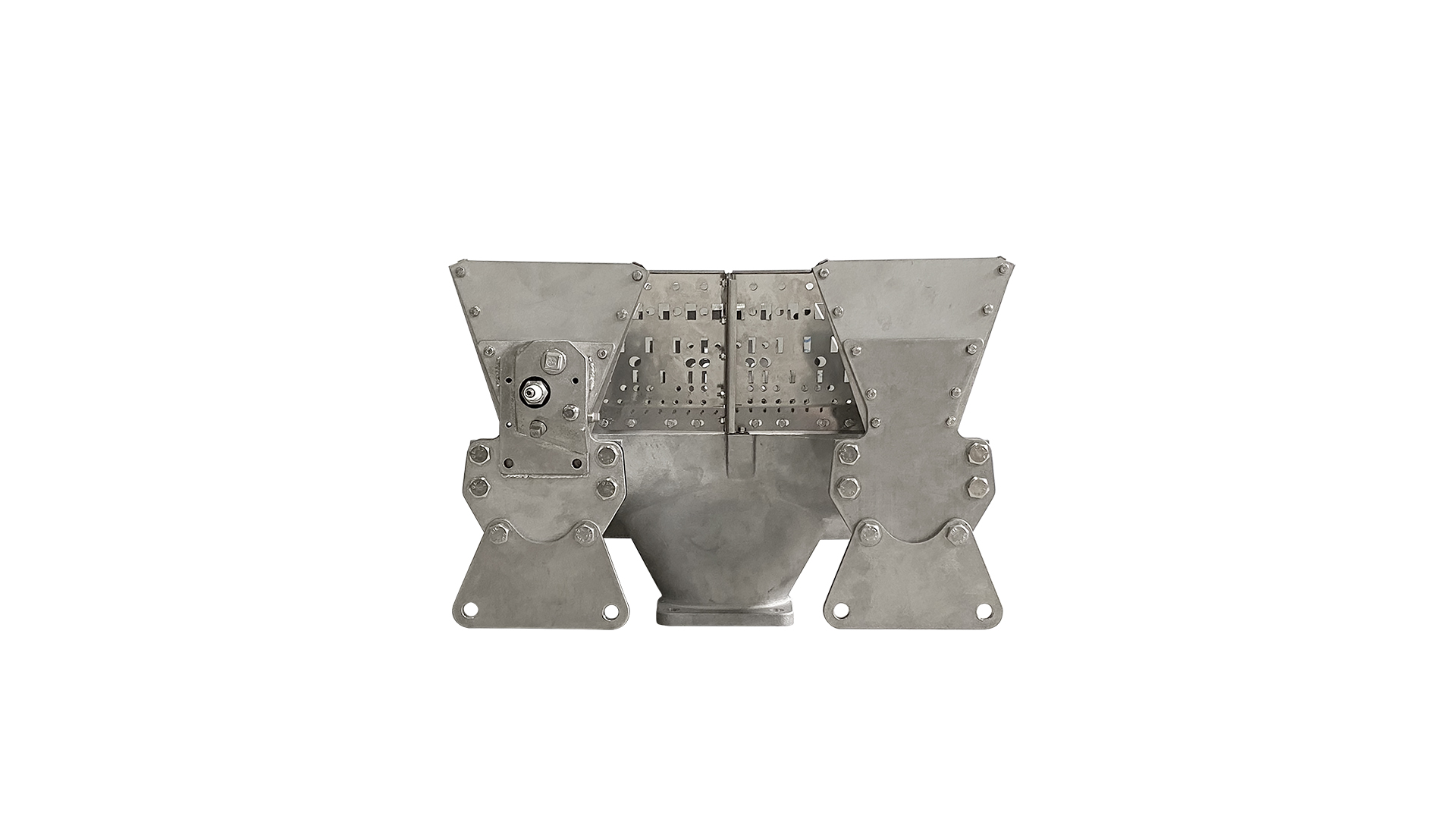

(duct burners)

Duct burners operate by injecting fuel into the hot exhaust stream of a gas turbine. The remaining oxygen in the exhaust supports combustion, raising the temperature of the gases before they enter a heat recovery steam generator (HRSG) or other downstream processes. Key components include a fuel injection system for delivering natural gas or liquid fuel, a burner grid or linear array for even fuel distribution, flame stabilizers to maintain consistent combustion, and a control system to regulate fuel flow and monitor performance.

Since duct burners leverage waste heat, they significantly improve thermal efficiency without requiring additional fuel combustion in a separate unit.

(duct burners for dry)

Duct burners provide several key benefits, including increased power output by raising exhaust gas temperature for higher steam production in HRSGs. They improve fuel efficiency by maximizing energy recovery from turbine exhaust, reducing overall fuel consumption compared to standalone boilers. Their operational flexibility allows them to be activated on-demand, providing supplemental heat during peak loads or compensating for turbine performance drops.

Modern duct burners also contribute to lower emissions, incorporating low-NOx designs to minimize nitrogen oxide emissions and ensure compliance with environmental regulations. Additionally, they serve as a cost-effective retrofit solution, often proving more economical than upgrading an entire turbine system while delivering a high return on investment.

(duct burners for drying equipment)

Duct burners are widely used in combined cycle power plants, where they enhance steam generation and increase overall plant efficiency by 5-15%. In cogeneration (CHP) systems, they provide additional heat for industrial processes, district heating, or absorption chillers. The petrochemical and refining industries utilize them in flare gas recovery and process heating, reducing waste and operational costs. Some advanced turbines in aerospace and marine power systems also integrate duct burners for auxiliary power units.

(duct burners for air heater)

When choosing a duct burner, compatibility with gas turbine exhaust is crucial, including factors such as exhaust oxygen content (typically 12-16% for optimal combustion), temperature, and flow rate. The fuel type and burner design must also be considered, with natural gas being the most common fuel, though some systems support diesel or syngas. The burner’s configuration should match the duct geometry, whether linear or grid-based.

Emissions control is another critical factor, with selective catalytic reduction (SCR) systems sometimes needed for NOx compliance, and staged combustion helping reduce pollutant formation. Maintenance and durability should also be evaluated, with high-temperature materials like stainless steel and ceramic coatings preventing corrosion, and automated controls minimizing manual intervention.

(air heater gas burner)

(air heater gas burner)

Emerging advancements in duct burner technology include AI-optimized combustion control, where machine learning algorithms adjust fuel flow in real time for peak efficiency. Another trend is the development of hydrogen-ready burners, adapting duct burners for hydrogen-blended fuels to support decarbonization efforts. Modular and scalable designs are also gaining traction, offering plug-and-play systems that simplify installation in diverse industrial setups.

(duct burner manufacturer)

Duct burners play a pivotal role in maximizing the efficiency of gas turbine systems, offering cost savings, flexibility, and improved performance. Whether used in power generation, cogeneration, or industrial heating, they provide a sustainable and economical solution for energy-intensive applications. For industries looking to enhance turbine output, reduce fuel costs, and meet emission standards, integrating a high-efficiency duct burner is a strategic investment.