Duct burners are vital combustion systems used extensively across industrial sectors to boost thermal efficiency and operational flexibility. These systems are installed within the ducts of gas turbines, heat recovery steam generators (HRSGs), or other exhaust streams to increase the temperature of process gases. Utilizing natural gas as the primary fuel, duct burners provide a reliable and efficient method for meeting high energy demands in various industrial applications. This article explores the functionality, benefits, and industrial uses of duct burners, with a focus on natural gas-fueled systems.

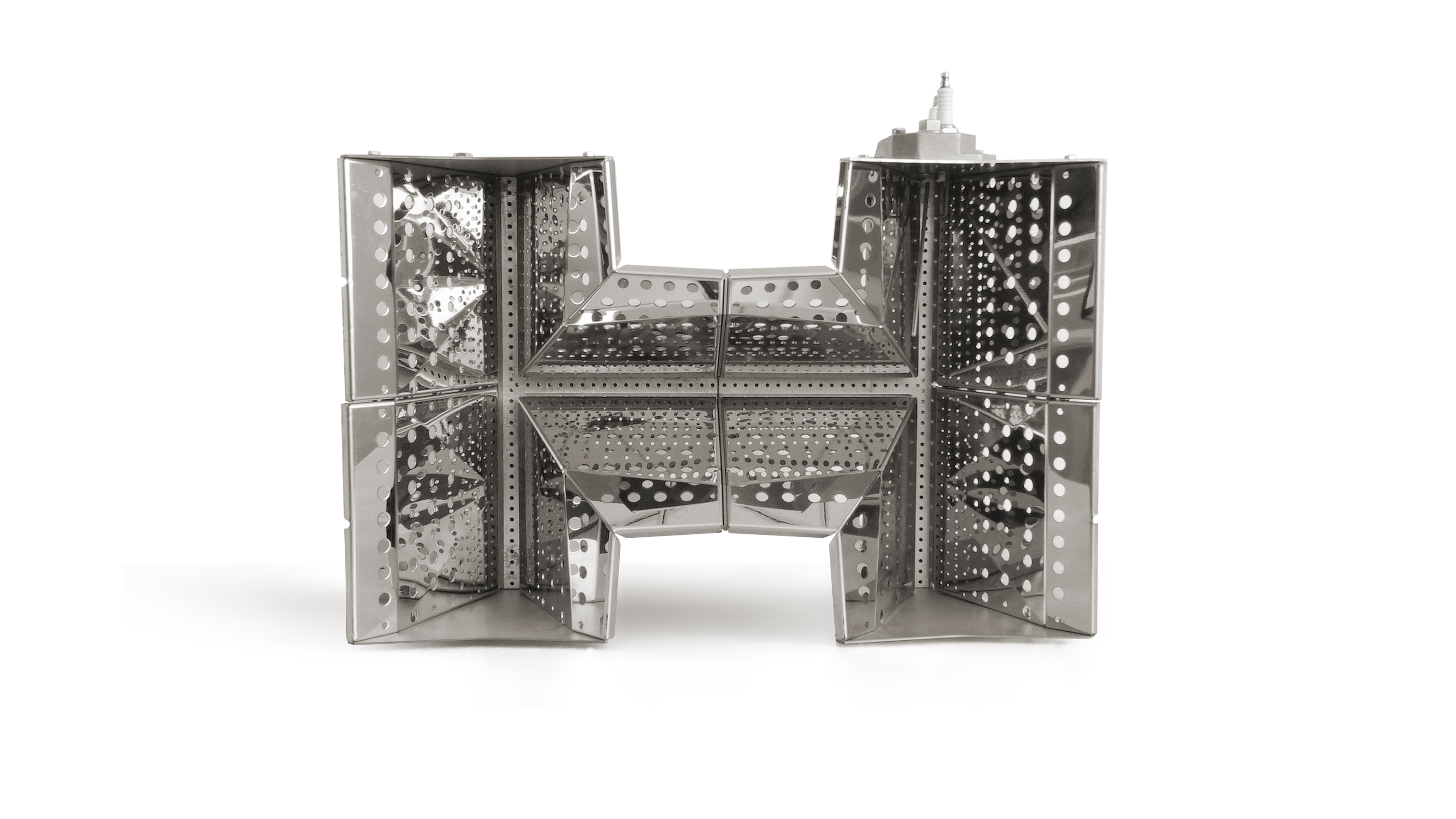

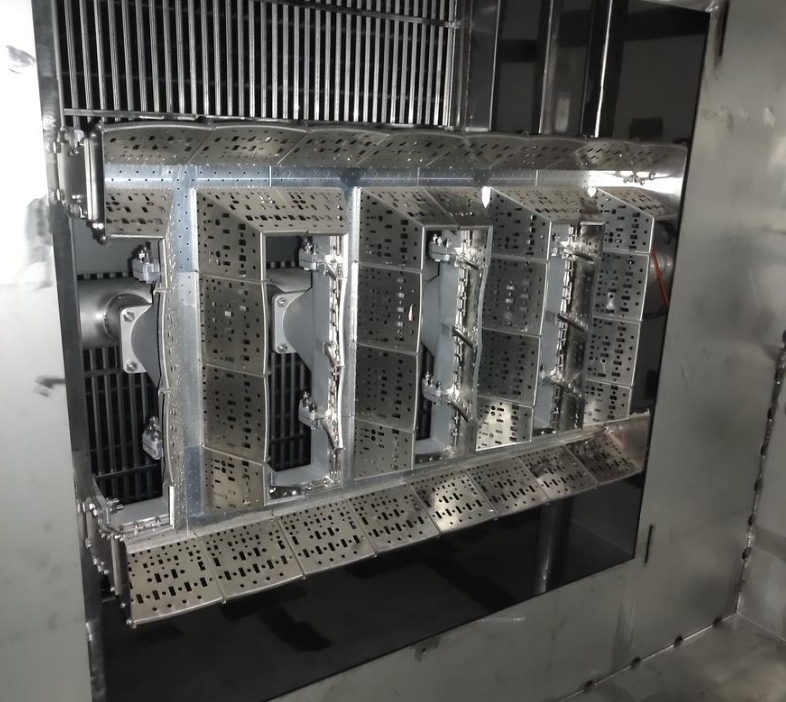

A duct burner operates by injecting natural gas into an exhaust or air stream, where it combusts to release additional heat. This process occurs within a dedicated duct or chamber, ensuring safe and controlled combustion. The design typically includes fuel injectors, igniters, and flame stabilization components to maintain efficient and stable operation. By leveraging the existing oxygen in the exhaust stream, duct burners enhance energy output without requiring significant additional infrastructure. This makes them an economical solution for industrial plants seeking to maximize their energy efficiency.

Natural gas is the preferred fuel for duct burners due to its combustion characteristics and availability. It burns cleanly, producing fewer emissions compared to other fossil fuels like coal or oil. This aligns with increasingly stringent environmental regulations and supports sustainability goals. Additionally, natural gas offers high energy density and consistent quality, ensuring reliable performance in duct burner applications. Its widespread infrastructure also simplifies supply logistics for industrial facilities, reducing operational complexities.

Duct burners are widely used in industries requiring hightemperature processes or supplementary heating. In the power generation sector, they are integrated into HRSGs to enhance steam production for electricity generation. Chemical and petrochemical plants employ duct burners to maintain optimal temperatures in reactors and furnaces. They are also common in metallurgy, glass manufacturing, and ceramics production, where precise temperature control is critical. By providing additional heat on demand, duct burners help these industries maintain productivity and efficiency.

The primary benefit of duct burners is their ability to improve overall system efficiency. In combined cycle power plants, for example, duct burners increase the heat input to HRSGs, resulting in higher steam output and greater electricity generation. This flexibility allows plants to respond quickly to fluctuating energy demands without compromising performance. Moreover, duct burners can compensate for variations in exhaust gas temperature or flow, ensuring consistent process conditions in industrial settings.

Effective duct burner design focuses on fuelair mixing, flame stability, and heat distribution. Natural gas injectors must be positioned to achieve uniform combustion and avoid hot spots that could damage equipment. Materials must withstand high temperatures and corrosive environments. Operational strategies include modulating fuel flow based on process requirements and monitoring emissions to ensure compliance. Regular maintenance is essential to sustain performance and prevent issues such as clogging or wear.

With natural gas as the fuel, duct burners contribute to lower emissions of sulfur oxides (SOx), particulate matter, and carbon dioxide compared to liquid or solid fuels. However, nitrogen oxides (NOx) formation remains a concern due to high combustion temperatures. Modern duct burners incorporate low-NOx technologies, such as staged combustion or flue gas recirculation, to minimize these emissions. Adhering to environmental standards is crucial for industrial operators, and duct burners designed for natural gas help meet these requirements.

Duct burners are indispensable components in industrial energy systems, offering a efficient and flexible method for supplemental heating. Their compatibility with natural gas ensures clean, reliable operation across various applications, from power generation to manufacturing. As industries continue to prioritize efficiency and sustainability, duct burners will play an increasingly important role in optimizing energy use and reducing environmental impact. By understanding their benefits and applications, industrial operators can make informed decisions to enhance their processes.