In the aluminum processing and smelting industry, the efficiency and energy consumption of aluminum melting furnaces have always been key concerns for manufacturers. With increasingly stringent environmental and energy-saving requirements, traditional air-assisted combustion methods are gradually failing to meet production demands. In recent years, low-debris pure oxygen burners have emerged as an ideal solution for both upgrading existing aluminum melting furnaces and new project installations, thanks to their outstanding performance.

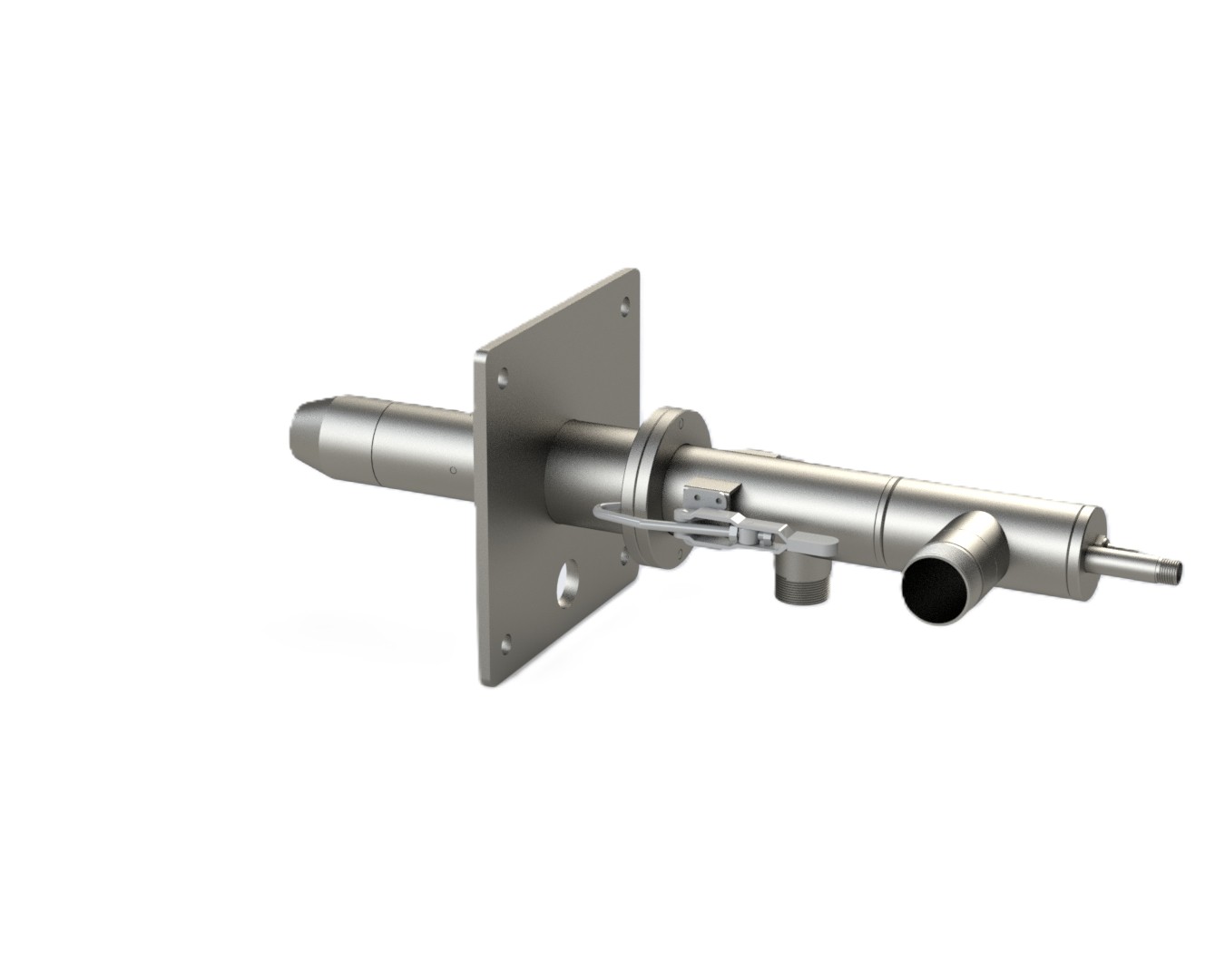

(low-debris pure oxygen burner)

A low-debris pure oxygen burner is an advanced combustion system that uses pure oxygen instead of air as the oxidizer. By optimizing the combustion process, it achieves high temperatures, high efficiency, and low emissions. This type of burner significantly reduces oxidation loss of molten aluminum at high temperatures, improves metal recovery rates, and lowers fuel consumption—aligning perfectly with the current trend toward green manufacturing.

In practical aluminum melting applications, these burners demonstrate multiple advantages. First, they deliver notable energy savings. Because pure oxygen supports combustion, flame temperatures are higher, thermal radiation is stronger, and melting speeds increase, leading to a significant improvement in overall thermal efficiency. Many users report energy consumption reductions of over 20% compared to traditional equipment.

(pure oxygen burners)

Second, metal loss is greatly reduced. During aluminum melting, oxidation slag often forms, leading to metal waste. With pure oxygen combustion technology, nitrogen levels in the furnace are drastically reduced, minimizing oxidation reactions and significantly lowering burn-off rates. This is crucial for improving product yield and economic performance.

Additionally, environmental performance is exceptional. Pure oxygen combustion produces almost no nitrogen oxides (NOx) and very low CO emissions, helping companies easily comply with strict environmental standards and achieve cleaner production.

It is also worth highlighting that modern pure oxygen burners offer excellent operational adaptability. For example, some models support a turndown ratio of 5:1 or higher, allowing flexible adjustment of flame length and shape to suit various furnace types and process requirements. Integrated automatic ignition and flame monitoring functions further enhance operational convenience and safety.

In summary, the application of low-debris pure oxygen burners in aluminum melting furnaces provides an effective pathway to high-efficiency, energy-saving, and environmentally friendly production. As aluminum industry technology continues to advance, this type of advanced combustion technology is expected to see broader adoption, helping companies improve quality and efficiency while moving toward sustainable development.