The Superflame dual-fuel burner is a high-performance combustion device designed for high-temperature industrial processes. It is widely used in various applications, including waste gas incinerators (RTO/TO), heat treatment furnaces, non-ferrous metal smelting furnaces, roasting furnaces, hot air furnaces, drying ovens, and pyrolysis furnaces. Its excellent dual-fuel compatibility supports both oil and gas modes, providing users with significant operational flexibility and energy options.

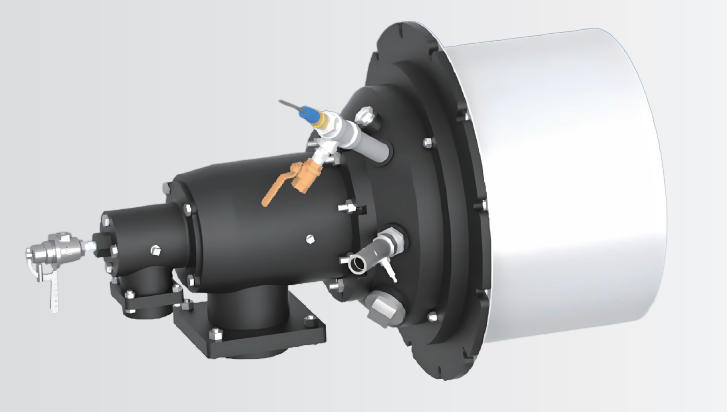

(Dual-Fuel Burner)

This burner offers several standout features. First, it is suitable for extreme environments with furnace temperatures up to 1,600°C, demonstrating exceptional thermal stability and durability. Second, the burner design emphasizes heat transfer efficiency, effectively maintaining uniform temperature within the furnace and avoiding process issues caused by localized overheating or uneven temperatures. Additionally, the product supports a wide range of temperature adjustments, meeting the requirements of both high- and low-temperature processes. Fuel and combustion air flow can be independently adjusted to suit different production conditions.

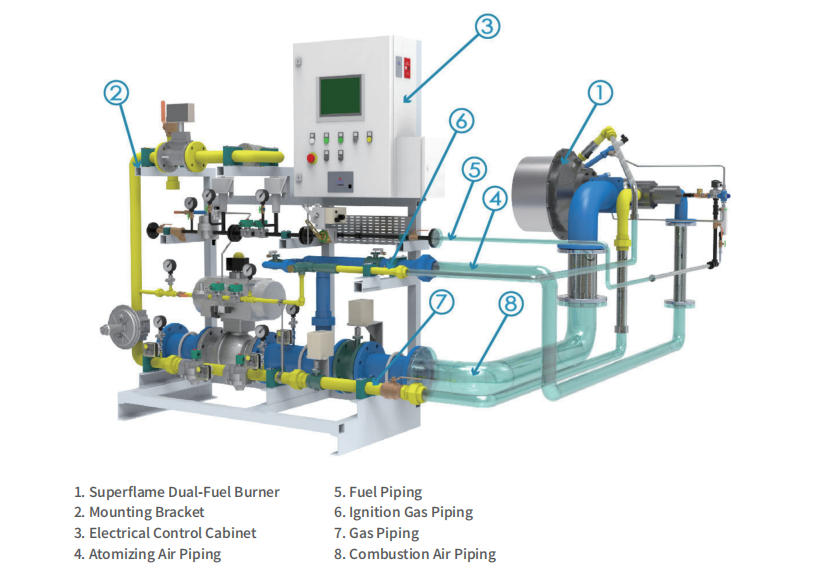

(Dual-Fuel Burner Combustion System)

In terms of environmental performance, the Superflame burner achieves low CO and NOx emissions, complying with stringent industrial emission standards. Its combustion adjustment ratio reaches an impressive 15:1, reflecting excellent load adaptability. Users can choose from six different power models, ranging from 430 kW to 6,300 kW. For example, the SFGO-6 model has a rated power of 430 kW, while the SFGO-10 model offers up to 6,300 kW. Each model provides detailed configurations for parameters such as flame length, air, and fuel flow, facilitating system integration and selection.

Regarding installation, the burner design balances practicality and simplicity. During installation, an opening must be made in the furnace wall according to the firebrick dimensions, with an appropriate margin预留. It is generally recommended that the opening size be at least 12 mm larger than the side length of the firebrick. Special gaskets and sealing materials are required during installation to ensure a tight seal between the burner and the furnace wall. After the first high-temperature operation, the refractory fiber must be inspected and replenished to ensure long-term safe and efficient operation.

(Oil and gas dual-purpose burner manufacturers)

In summary, the Superflame dual-fuel burner, with its high efficiency, environmental friendliness, and flexibility, is an ideal choice for many industrial heating applications. Whether in terms of energy consumption control, temperature precision, or environmental compliance, this product demonstrates significant advantages, helping companies achieve energy savings and enhance process performance.