(Low NOx Burner)

In today's industrial sector with increasingly stringent environmental requirements, low NOx burners have become core components in various industrial furnaces and boilers due to their excellent emission reduction and stable performance. Especially for high-temperature industrial applications, choosing an efficient and stable low NOx burner not only meets environmental regulations but also effectively improves combustion efficiency and reduces operating costs.

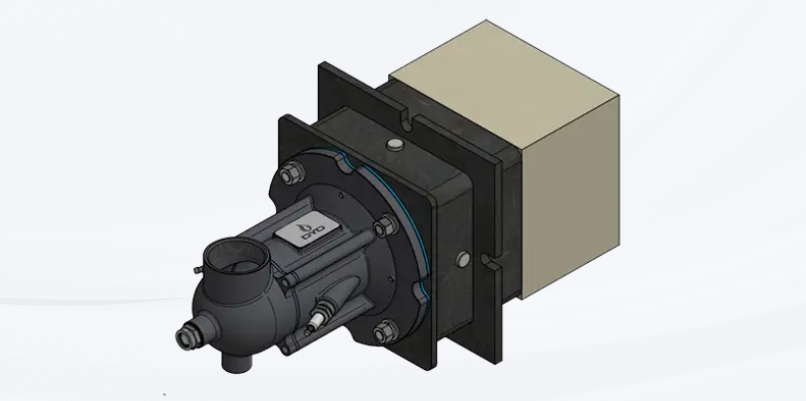

Among numerous burner manufacturers, the DNX-C/M series high-speed low NOx burners stand out with their unique technical advantages. This series features a delayed mixing cup structure that slows down the mixing process of air and fuel gas in the combustion chamber, ensuring stable combustion temperature control and significantly reducing nitrogen oxide (NOx) formation. Furthermore, the high exit flame velocity effectively entrains furnace flue gas, further suppressing pollutant emissions. Suitable for various high-temperature industrial environments, it can handle maximum furnace temperatures up to 1200°C.

(Low nitrogen burner parameters)

Beyond superior environmental performance, the DNX-C/M series burners are meticulous in material selection. The flame tube and burner head are made of high-temperature resistant stainless steel SUS 310S, ensuring a robust structure and long service life. The combustion chamber utilizes refractory brick material, adaptable to complex conditions with preheated air temperatures ranging from 250°C to 500°C. Additionally, this burner series offers a wide turndown ratio of 1:22 and supports multiple fuel types like Natural Gas and Coke Oven Gas, providing excellent fuel flexibility and operational adaptability.

Selecting a professional low NOx burner manufacturer is crucial for any business. A quality manufacturer not only provides reliable products but also recommends suitable models and configurations based on specific user needs. The DNX-C/M series covers a wide power range, from 66 kW to 1240 kW, meeting the requirements of users of different scales, making it a cost-effective choice highly recommended by many manufacturers.

(low NOx burner manufacturer)

In summary, low NOx burners play a vital role in driving the energy-saving and eco-friendly transformation of industrial combustion equipment. When making a purchase decision, businesses should comprehensively consider burner performance, material quality, and manufacturer support. Choosing a mature, stable, and efficient product like the DNX-C/M series enables truly efficient and clean combustion in practical applications, supporting your company's journey towards green and sustainable development.