In the industrial heating sector, efficiency and environmental compliance are top priorities. As emissions regulations tighten globally, Low NOx burners have become essential for upgrading boilers and industrial furnaces. This article explores what a Low NOx burner is, how it works, and how to find a reliable Low NOx burner manufacturer.

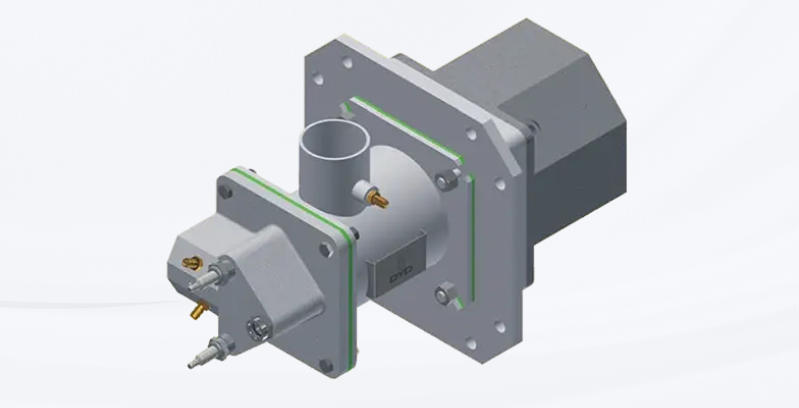

(Low-NOx Burner)

A Low NOx burner is designed specifically to reduce the emission of nitrogen oxides (NOx), a major pollutant. It achieves this through advanced engineering that optimizes flame structure, controls combustion temperature, and manages the air-fuel mixture. For instance, advanced models like the D-EGR-HFM High-Temperature Ultra-Low NOx Burner utilize a super-stable aerodynamic flame stabilization technology. This allows for operation with high excess air, producing a cooler flame and maintaining lower furnace temperatures, which directly suppresses thermal NOx formation.

High-quality Low NOx burners are built with robust materials and offer a wide performance range. Key components often include a cast iron or carbon steel air casing, a heat-resistant SUS 310S combustion head, and a silicon carbide or refractory material combustion chamber capable of withstanding furnace temperatures up to 1200°C. Supporting preheated air up to 350°C enhances overall efficiency. These burners typically run on natural gas or LNG, offer a high turndown ratio of 1:20, and are available in a power range from 108kW to 720kW to suit various applications.

(Low nitrogen burner parameters)

Choosing the right burner is only half the battle; selecting a qualified manufacturer is crucial. A reputable Low NOx burner manufacturer will have strong R&D capabilities, in-house testing facilities, and a proven track record. They should offer a comprehensive product portfolio with different models and provide customized solutions based on your specific furnace type, fuel, and operational needs.

When sourcing a Low NOx burner, look beyond the basic specifications like power and dimensions. Evaluate the manufacturer's technical support, project experience, and after-sales service. We recommend comparing several manufacturers, reviewing their case studies, and seeking customer testimonials to find a trustworthy partner with solid expertise.

(Low nitrogen burner manufacturers)

In summary, investing in a modern Low NOx burner is a strategic decision that helps companies meet environmental standards while improving energy efficiency and reducing operational costs. In today's world, where sustainability is key, partnering with the right technology and a professional manufacturer is vital for long-term success.

We hope this overview provides valuable insights for your equipment selection process. For more detailed information, we encourage you to contact several professional manufacturers to find the optimal solution for your needs.